how to reduce the cost of wire edm

Effective Strategies for Reducing Wire EDM Costs

Wire EDM offers numerous advantages, such as high precision and the ability to cut complex shapes, it can also be an expensive process. However, by implementing certain strategies, manufacturers can effectively reduce the cost of Wire EDM without compromising on quality or efficiency.

One of the most effective strategies for reducing Wire EDM costs is optimizing the cutting parameters. By carefully selecting the appropriate cutting speed, wire tension, and flushing conditions, manufacturers can significantly improve the efficiency of the process. For example, increasing the cutting speed can reduce the machining time, resulting in lower costs. Similarly, adjusting the wire tension and flushing conditions can help minimize wire breakage and improve the overall cutting performance.

Another important aspect to consider when aiming to reduce Wire EDM costs is material selection. Choosing the right material can have a significant impact on the overall cost of the process. Some materials, such as titanium or exotic alloys, are more difficult to machine and may require additional time and resources. By selecting materials that are easier to machine, manufacturers can reduce the machining time and, consequently, the cost of Wire EDM.

Furthermore, proper maintenance and regular servicing of Wire EDM machines are crucial for cost reduction. Neglecting maintenance can lead to increased downtime, decreased productivity, and higher repair costs. By implementing a preventive maintenance program and adhering to the manufacturer’s recommendations, manufacturers can ensure that their machines are operating at peak efficiency, minimizing the risk of unexpected breakdowns and costly repairs.

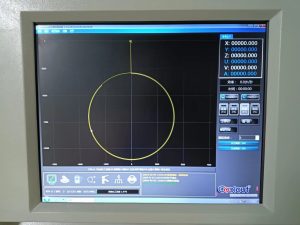

Investing in advanced software and automation systems is another effective strategy for reducing Wire EDM costs. These technologies can optimize the programming and control of the machines, resulting in improved efficiency and reduced material waste. Additionally, automation systems can minimize human error and increase productivity, ultimately leading to cost savings.

High speed machining with advanced wire edm software and control system

Collaborating with experienced Wire EDM service providers can also help reduce costs. Outsourcing certain projects to specialized companies can be more cost-effective than investing in expensive machinery and training personnel. These service providers often have the expertise, equipment, and resources to handle complex projects efficiently, allowing manufacturers to focus on their core competencies and reduce overall costs.

Lastly, continuous improvement and process optimization are essential for cost reduction in Wire EDM. By regularly reviewing and analyzing the manufacturing processes, manufacturers can identify areas for improvement and implement changes accordingly. This can include streamlining workflows, eliminating unnecessary steps, and adopting new technologies or techniques that offer cost savings.

In a word,reducing the cost of Wire EDM is achievable through various strategies. By implementing these strategies, manufacturers can successfully reduce Wire EDM costs and enhance their competitiveness in the market.