cnc edm wire cut machine working principle

CNC edm wire cut machine is a type of computer numerical control (CNC) machine that use electrical discharge machining (EDM) to cut metal parts. These machines are used in a variety of industries, including aerospace, automotive, mold making and other metal cutting. They are unique in that they can cut complex shapes with high precision and accuracy.we need to figure out the principle of wire cut,if we want to learn more the unique features.

The working principle of CNC edm wire cut machine is based on the principle of electrical discharge machining. This process uses a thin electrode wire usually made of brass,molybdenum or other alloy to cut through metal parts.The electrode wire is negative electrode and the workpiece is positive electrode, The electric spark will generate between wire and workpiece when they get close enough,then the electric sparks form high temperatures that center temperature will be 5000 to 6000 Celsius that could corrode the metal workpiece materials to cu.The wire is running and the electric discharge pulse power is working during processing,and working-fluid is continuously flushes the processing area to remove the micro metal chips,the worktable moving is controlled by the edm wire cutting machine software program which is used to control the speed and direction of the wire, as well as the voltage and current of the electrical discharge.the control program also adjust the position of wire reliative to the workpiece in accordance with grating ruler or other sensors,allowing for precise machining.

In this processing,the electrode wire and workpiece do not contact so there is almost no cutting force between them,that’s the one unique of edm wire cut machine from other machine tools.

the main parts for the edm wire cut machine working:

a.electrode wire running system Z axis

b.electric discharge pulse power

c.X,Y,U,V axis worktable

d.circulating cooling system

e.Control software system

f. Position sensors

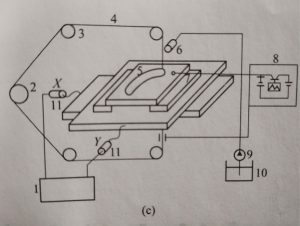

Following molybdenum wire cut machine working Drawing

1.control system, 2.wire rolling cylinder, 3.guide wheel, 4.molybdenum wire, 5. workpiece

6. nozzle, 7.insulating plate, 8.pulse power, 9.water pump, 10.working-fluid tank 11.motor

The other feature of CNC edm wire cut machine is their ability to cut hard metal workpiece with high precision and accuracy. This is due to the fact that the high temperature erode hard metal materials , allowing for intricate shapes to be cut. Additionally, the wire can be used to cut materials that are difficult to machine with traditional methods, such as hard alloys, titanium and stainless steel etc. edm wire cut machine is an invaluable tool for many industries.