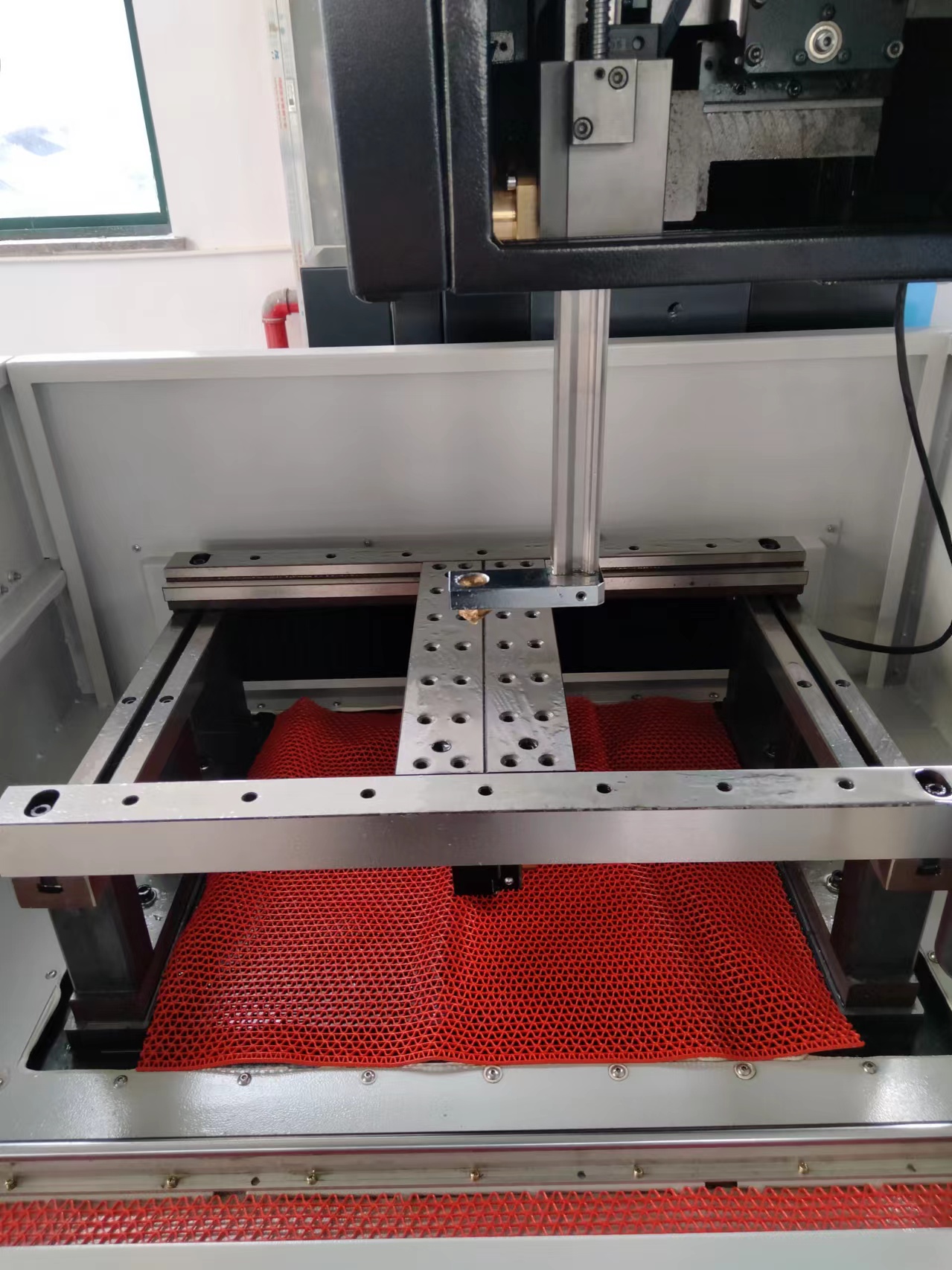

fixture of edm wire cut machine

EDM wire cut machines have become a staple in the manufacturing industry due to their precision and efficiency in cutting various materials. One key component of EDM wire cut machines that plays a crucial role in their operation is the fixture. Fixtures are essential in holding the workpiece securely in place during the cutting process, ensuring accurate and consistent results. In this article, we will explore the advantages of using edm wire cut machine fixtures in the design and manufacturing process.

Using fixtures in EDM wire cut machines is the ability to achieve high levels of precision. Fixtures are designed to securely hold the workpiece in place, minimizing any movement or vibration during the cutting process. This stability allows for precise and accurate cuts to be made, resulting in high-quality finished products. Additionally, fixtures can be customized to accommodate different shapes and sizes of workpieces, further enhancing the precision of the cutting process.

fixtures is the ability to increase efficiency and productivity. By securely holding the workpiece in place, fixtures allow for continuous cutting without the need for constant adjustments or repositioning. This streamlines the manufacturing process and reduces downtime, ultimately increasing productivity and output. Additionally, fixtures can be designed to hold multiple workpieces simultaneously, further maximizing efficiency and throughput.

In addition to precision and efficiency, fixtures in EDM wire cut machines also offer versatility in design and customization. Fixtures can be tailored to meet the specific requirements of each individual project, allowing for greater flexibility in the manufacturing process. Whether it be complex shapes, intricate designs, or unique materials, fixtures can be designed to accommodate a wide range of workpieces, making them an essential tool for manufacturers looking to expand their capabilities.

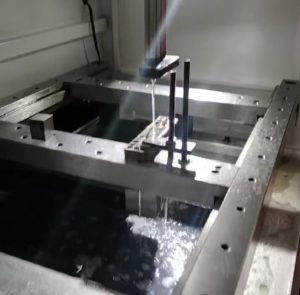

The fixtures in EDM wire cut machines can also improve safety in the workplace. By securely holding the workpiece in place, fixtures help to prevent accidents and injuries that may occur due to movement or slippage during the cutting process. This not only protects the operator but also ensures the integrity of the workpiece and the machine itself. Additionally, fixtures can be designed with safety features such as guards and sensors to further enhance workplace safety.

fixtures can fix the aluminum workpiece safely video

The advantages of using fixtures in EDM wire cut machines are clear. From precision and efficiency to versatility and safety, fixtures play a crucial role in the design and manufacturing process. By utilizing fixtures in EDM wire cut machines, manufacturers can achieve high levels of accuracy, increase productivity, and enhance workplace safety. As technology continues to advance, fixtures will undoubtedly remain a fixture in the manufacturing industry, providing essential support for the cutting-edge capabilities of EDM wire cut machines.