material properties influencing surface roughness in edm wire cut workpiece

Material properties play a crucial role in determining the surface roughness of EDM wire cut workpieces. The surface roughness of a workpiece refers to the irregularities or deviations from the ideal smooth surface. Achieving a desired surface finish is essential in many industries, such as molding,aerospace, automotive, and medical, where precision and quality are of utmost importance.In general,the min.surface roughness of molybdenum wire cut machine is Ra0.6um,the brass wire edm machine is Ra0.4um.

One of the primary material properties that influence surface roughness is the hardness of the workpiece material. Harder materials tend to produce a higher surface finish compared to softer materials. This is because the EDM wire cutting process involves the high temperature erosion of the workpiece material using electrical discharges.Harder materials are more resistant to this erosion,but are more difficulte to form Oxide layers, and more resistant to deformation which allow for the working fluid is fully working in the erosion area, resulting in a better surface finish.

Another material property that affects surface roughness is the thermal conductivity of the workpiece material. Materials with high thermal conductivity, such as copper and aluminum, tend to produce a smoother surface finish compared to materials with low thermal conductivity, such as stainless steel or titanium. This is because high thermal conductivity helps in dissipating the heat generated during the EDM process, reducing the chances of thermal damage and resulting in a smoother surface.wire edm cutting aluminum video

The composition of the workpiece material also plays a significant role in determining surface roughness. Materials with impurities or alloying elements can have a detrimental effect on the surface finish. These impurities can cause irregularities and inconsistencies in the erosion process, leading to a rougher surface. Additionally, the presence of certain elements, such as sulfur or phosphorus, can promote the formation of a brittle layer on the workpiece surface, further increasing the surface roughness.

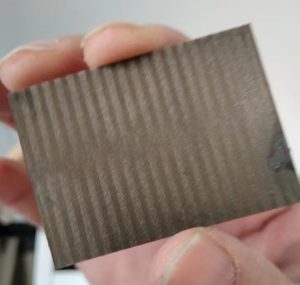

The grain structure of the workpiece material is another factor that influences surface roughness. Fine-grained materials tend to produce a smoother surface finish compared to coarse-grained materials. This is because fine-grained materials have a more uniform microstructure, which allows for a more controlled and consistent erosion process. On the other hand, coarse-grained materials have larger grain boundaries, which can result in uneven material removal and a rougher surface.

The presence of residual stresses in the workpiece material can also affect surface roughness. Residual stresses can be introduced during the manufacturing process or due to material properties. These stresses can cause distortion or warping of the workpiece, leading to an uneven surface finish. Minimizing or controlling residual stresses through proper heat treatment or stress-relieving techniques can help improve surface roughness.

Several material properties for surface roughness of workpieces. Those all play a significant role in determining the final surface finish. Understanding these factors and their interactions can help manufacturers optimize the EDM wire cutting process and achieve the desired surface roughness for various applications.but there ‘s more factors to it than those,working-fluid,electrode wire,guide pulley,pulse power supply,that all make a difference. As a wire cut edm machine manufacturer,we have R&D the latest high quality pusle power and control software about the surface roughness of edm wire cut,and we’ll tell you more about it later.