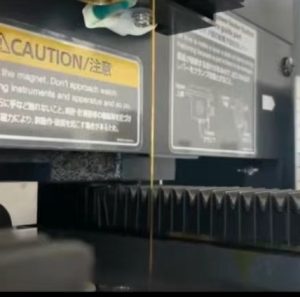

copper wire electrodes in edm wire cut machine

The brass wire electrode, which plays a crucial role in the machining process. There are several types of wire electrode materials that can be used in edm wire cut machine, with copper being one of the most popular choices.

Copper wire electrodes offer a number of benefits that make them ideal for use in edm wire cut machine. One of the main advantages of copper wire electrodes is their high conductivity. Copper is an excellent conductor of electricity, which allows for efficient and precise machining. The high conductivity of copper wire electrodes helps to ensure a stable and consistent electrical discharge during the machining process, resulting in high-quality surface finishes and accurate cuts.

These wire electrodes also offer excellent thermal conductivity. This means that copper wire electrodes are able to dissipate heat quickly and effectively during the machining process. This is important because excessive heat buildup can lead to thermal damage to the workpiece and the wire electrode itself. By using copper wire electrodes with high thermal conductivity, manufacturers can minimize the risk of thermal damage and achieve better machining results.

Another benefit of using copper wire electrodes in edm wire cut machine is their superior machinability. Copper is a soft and ductile metal, which makes it easy to machine and shape into the desired wire electrode profile. This allows for greater flexibility in the design and manufacturing of wire electrodes, enabling manufacturers to create custom shapes and sizes to suit specific machining requirements.

Wire electrodes made of copper are known for their excellent wear resistance. The high hardness and durability of copper make it a reliable choice for use in edm wire cut machine, where the wire electrode is subjected to high levels of wear and abrasion during the machining process. Copper wire electrodes are able to withstand the rigors of EDM machining and maintain their shape and integrity over extended periods of use, resulting in longer tool life and reduced maintenance costs.

Using copper wire electrodes in edm wire cut machine are clear. From their high conductivity and thermal conductivity to their superior machinability and wear resistance, copper wire electrodes offer a range of advantages that make them an excellent choice for manufacturers looking to achieve high-quality machining results. By choosing copper wire electrodes for edm wire cut machine, manufacturers can improve efficiency, accuracy, and reliability in their machining processes, ultimately leading to better overall productivity and profitability.