edm wire cut machine definition

edm wire cut machine, also known as wire electrical discharge machines, is a type of machining tool that use electrical discharges to shape and cut materials. This technology has revolutionized the manufacturing industry, allowing for precise and intricate cuts that were previously impossible to achieve. In this article, we will delve into the definition of EDM wire cut machines and explore their various applications and advantages.

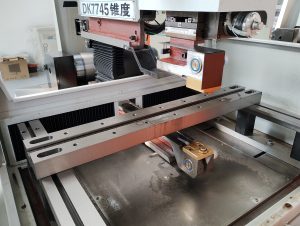

EDM wire cut machines work by using a thin, electrically charged wire to cut through conductive materials. The wire is guided by computer numerical control (CNC) software, which controls the movement and positioning of the wire. As the wire passes through the material, electrical discharges occur between the wire and the workpiece, eroding the material and creating the desired shape or cut.

One of the key advantages of EDM wire cut machines is to cut complex shapes with high precision. As the numerical control technology has already used for the edm wire cut machine,that can read the workpiece Autocad two-dimensional diagrams and work in accordance with the pragram software.the workpiece cutted roundness of D15mm shape accuracy less than 0.01mm, and the positional accuracy within 300mm less than 0.012mm,Traditional cutting methods, such as milling or grinding, often result in rough edges or imprecise cuts. EDM wire cut machines, on the other hand, can achieve extremely tight tolerances and produce smooth, burr-free cuts. This makes them ideal for applications that require intricate details or tight fits, such as in the aerospace or medical industries.

EDM wire cut machines is their ability to cut hard materials. Unlike traditional cutting methods, which can be limited by the hardness of the material, EDM wire cut machines can cut through even the toughest materials, such as hardened steel or titanium. becasue the working method of edm wire cut machine is eroding the materials by high-temperature 5000 to 6000 Degree Celsius,the electrode wire is not contacting the workpiece in the process,therefore the machine can cut the hard materials,This makes them a popular choice for industries that work with these types of materials, such as the automotive or tooling industries.

These machines also offer excellent surface finish. the working pulse width is 0.001us,and the min feed rate of worktable is 0.001um,and no-mechanical friction on the surface of workpiece,that allow for the good surface finish.The electrical discharges used in the cutting process create a smooth surface, eliminating the need for additional finishing operations. This not only saves time and money but also ensures a high-quality surface finish product.

inspect the surface roughness of workpiece video

Therefore EDM wire cut machines are used in a wide range of industries and applications. They are commonly used in the production of molds and dies, where precision and intricate details are crucial. They are also used in the manufacturing of gears, turbine blades, and other components that require high accuracy. Additionally, EDM wire cut machines are used in the production of prototypes, allowing for quick and cost-effective testing of new designs.

EDM wire cut machines are a powerful tool in the manufacturing industry. Their ability to cut complex shapes with high precision, cut hard materials, and provide excellent surface finish make them an invaluable asset for a wide range of applications. Whether it’s in the aerospace, medical, automotive, or tooling industry, EDM wire cut machines have proven to be a game-changer. As technology continues to advance, we can expect even more advancements in EDM wire cut machines, further pushing the boundaries of what is possible in the world of manufacturing.