Essential EDM Wire Cut Accessories for Precision and Efficiency

EDM wire cut accessories play a crucial role in achieving precision and efficiency in the wire cutting process. These accessories are designed to enhance the performance of EDM wire cut machines, ensuring accurate and smooth cuts. In this article, we will explore some essential EDM wire cut accessories that every precision engineer should have in their arsenal.

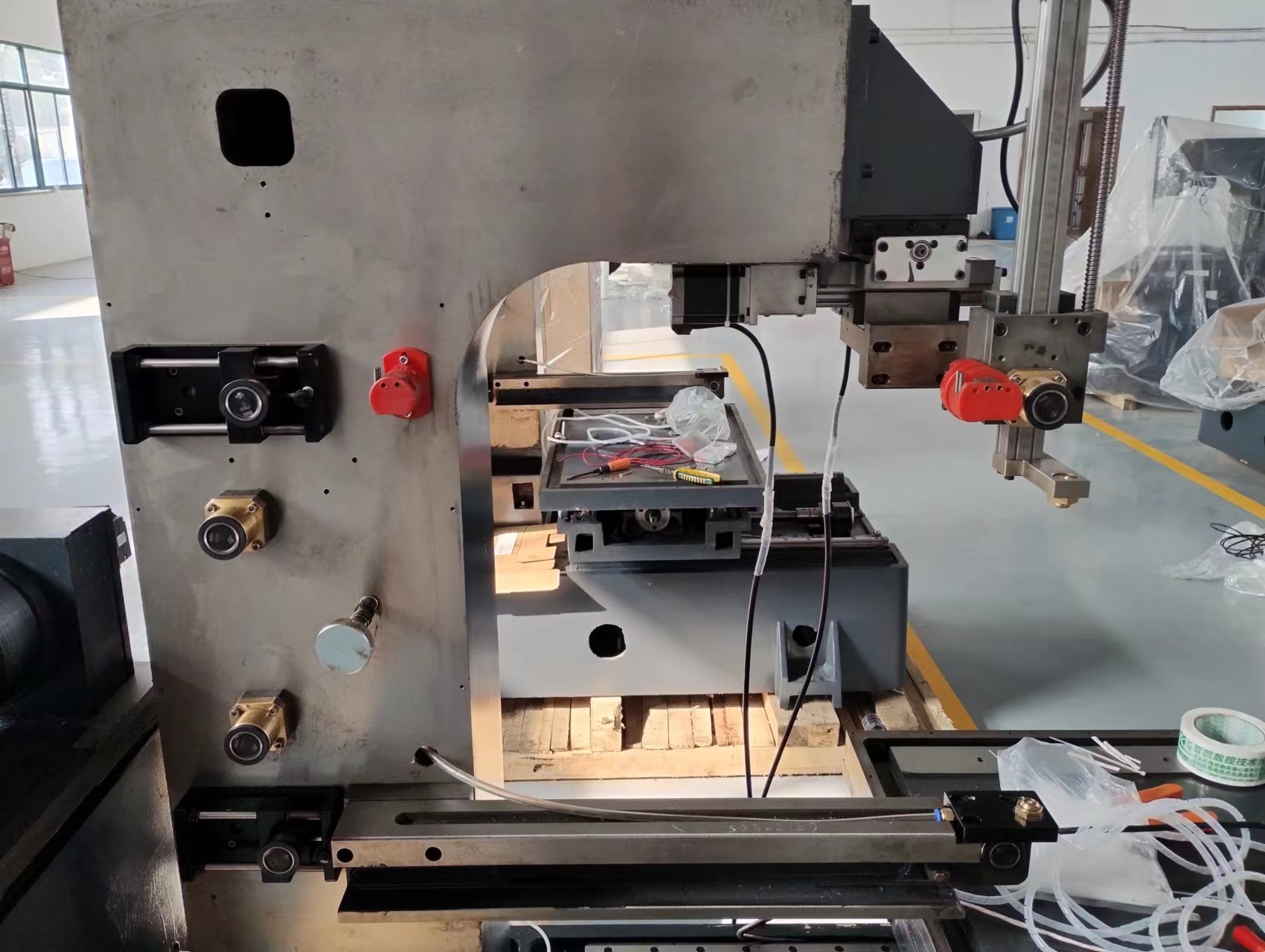

One of the most important accessories for EDM wire cut machines is the wire guide system. The wire guide system including guide pulley and wire guides is responsible for guiding the wire during the cutting process, ensuring that it stays on track and maintains the desired cutting path. A high-quality wire guide is essential for achieving precise and accurate cuts. It should be made from durable materials that can withstand the high temperatures and pressures involved in the wire cutting process.In general,the wire guide system has two wire guides and 5 to 8 guide pulleys.

Another essential accessory is the power feed contact made of carbide alloy. The power feed contact can deliver the electrical current to the electrode wire during the cutting process. It needs to have excellent conductivity to ensure a consistent and stable power supply. A high-quality power feed contact will minimize the risk of wire breakage and ensure a smooth and efficient cutting process.

To achieve precise and accurate cuts, EDM wire cut machines require a reliable flushing and filtration system. The system is responsible for removing the debris and particles generated during the cutting process,and filtering the particles by the filters in the tank, It helps to maintain a clean cutting environment, preventing any interference with the wire and ensuring a smooth and accurate cut. A well-designed flushing and filtration system should have a strong flow rate and be able to effectively remove all the debris from the cutting area.

EDM wire cut machines are equiped with a stable and reliable power supply. A voltage stabilizer is an essential accessory that helps to regulate the voltage supplied to the machine. It ensures a consistent and stable power supply, minimizing the risk of voltage fluctuations that can affect the cutting process. A voltage stabilizer will help to achieve precise and accurate cuts, even in areas with unstable power supply.

Lastly, EDM wire cut machines require a reliable wire tensioning system. The wire tensioning system is responsible for maintaining the tension of the wire during the cutting process. It ensures that the wire remains taut and does not sag or loosen, which can affect the accuracy of the cuts. A high-quality wire tensioning system will provide precise control over the wire tension, ensuring consistent and accurate cuts.

EDM wire cut accessories are essential for achieving precision and efficiency in the wire cutting process. These accessories, such as wire guide system, power feed contacts, flushing systems, filtration systems, voltage stabilizers, and wire tensioning systems, play a crucial role in enhancing the performance of EDM wire cut machines. Investing in high-quality accessories will ensure accurate and smooth cuts, leading to improved productivity and customer satisfaction.