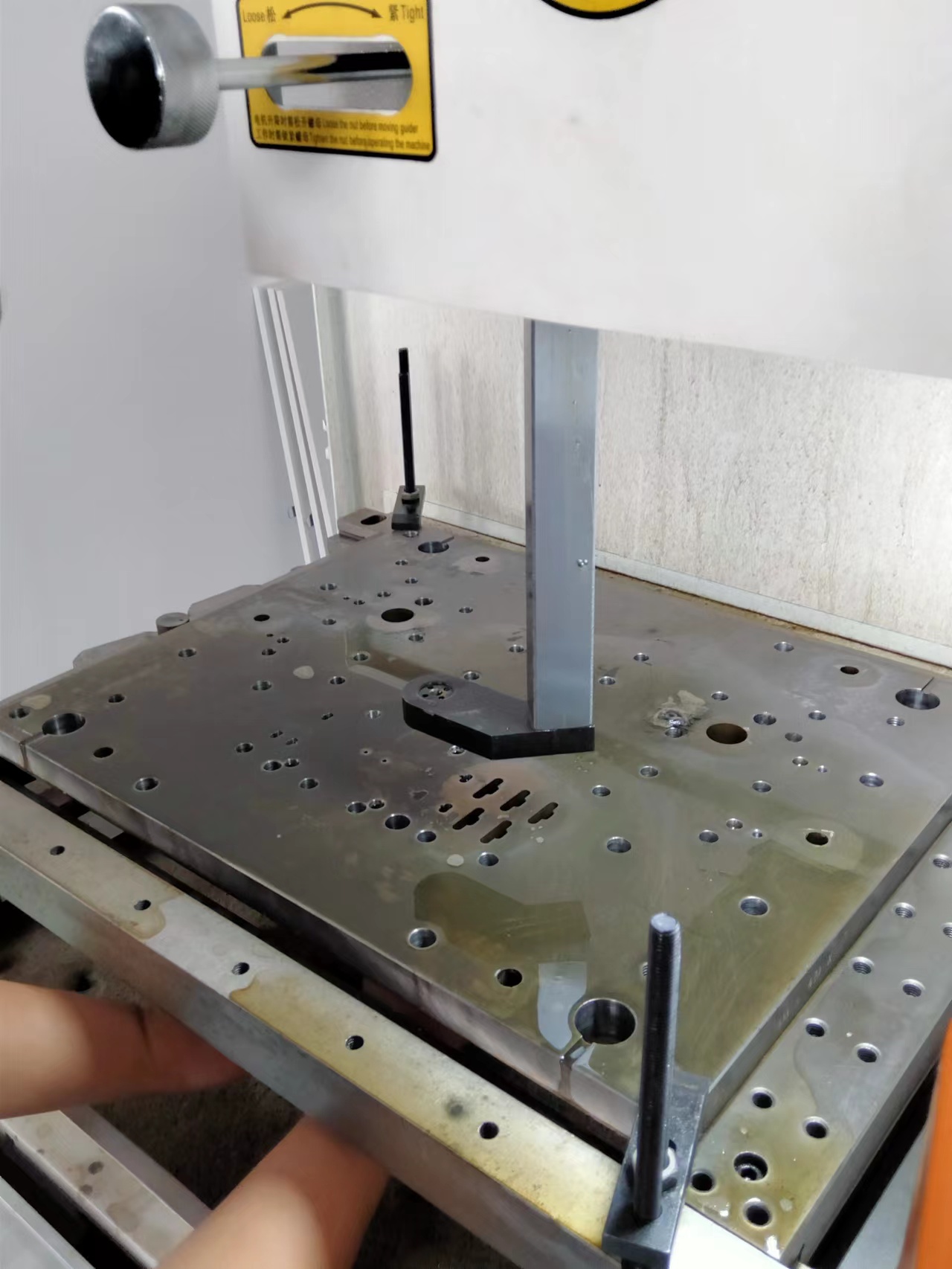

edm wire cut machine application

Electrical Discharge Machining (EDM) wire cut machines are becoming increasingly popular for precision machining. This technology is used to cut intricate shapes and patterns in a variety of materials, including metals, PCD, and ceramics. EDM wire cut machines offer a number of advantages over traditional machining methods, making them an attractive option for many applications.

One of the primary benefits of EDM wire cut machines is their accuracy. EDM wire cut machines use a thin wire to cut through the material, which allows for extremely precise cuts. This precision is especially beneficial when machining complex shapes and patterns, as it ensures that the finished product is exactly as intended. Additionally, EDM wire cut machines can be used to cut materials that are too hard or too brittle to be machined using traditional methods.

Another advantage of EDM wire cut machines is their speed. a latest no-electrolytic pulse power supply for edm wire cut has been created in recent years,that max. efficiency of wire cutting is 300mm²/min,so EDM wire cut machines can cut through materials quickly and efficiently, allowing for faster production times. This is especially beneficial for applications that require a large number of metal parts to be machined in a short amount of time. Additionally, EDM wire cut machines can be programmed to cut multiple parts at once, further increasing their efficiency.

Finally, cnc wire cut machines are relatively easy to use and maintain. The machines are designed to be user-friendly, and they require minimal setup and maintenance. This makes them ideal for applications that require frequent changes in the machining process. Additionally, EDM wire cut machines are relatively inexpensive, making them a cost-effective option for many applications. installation of moly-wire for the wire cut machine youtube video

Overall, EDM wire cut machines offer a number of advantages over traditional machining methods. Their accuracy, speed, and ease of use make them an attractive option for many applications. Additionally, their relatively low cost makes them a cost-effective choice for many businesses. For these reasons, EDM wire cut machines are becoming increasingly popular for precision machining.