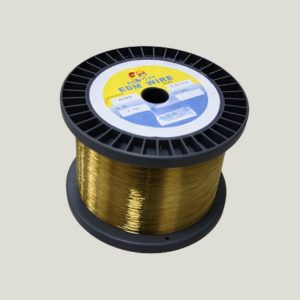

electrode wire of edm wire cut machine

Electrode wire is a crucial component in EDM wire cut machines, playing a significant role in the precision cutting process. This thin wire, typically made of brass or molybdenum, is used to create electrical discharges that erode the workpiece material, resulting in highly accurate cuts. There are several advantages to using electrode wire in EDM wire cut machines, making it a popular choice for industries that require precise and intricate cutting operations.

One of the primary advantages of using electrode wire in EDM wire cut machines is its ability to cut complex shapes with high precision. The thin diameter of the wire allows for tight corners and intricate details to be cut with ease, making it ideal for applications that require fine detailing. This level of precision is essential in industries such as aerospace, automotive, and medical, where accuracy is paramount.

Electrode wire is highly versatile and can be used to cut a wide range of materials, including metals, PCD, and composites. This versatility makes EDM wire cut machines with electrode wire suitable for a variety of applications, from prototyping and tooling to production runs and repairs. The ability to cut different materials with the same machine saves time and money, making electrode wire a cost-effective solution for many industries.

Another useage of electrode wire in EDM wire cut machines is the ability to achieve high surface finishes. The electrical discharge machining process produces smooth, burr-free cuts that require minimal post-processing, saving time and labor costs. This high-quality finish is essential for industries that require parts with tight tolerances and a polished appearance, such as the medical and electronics industries.the roughness of workpiece edm wire cut machine

Furthermore, electrode wire is durable and long-lasting, allowing for extended cutting operations without the need for frequent replacements. This durability reduces downtime and maintenance costs, making EDM wire cut machines with electrode wire a reliable and efficient solution for industrial cutting applications. The consistent performance of electrode wire ensures that each cut is precise and accurate, resulting in high-quality parts every time.

The electrode wire is an essential component in EDM wire cut machines, offering numerous advantages for industries that require precise and intricate cutting operations. Its ability to cut complex shapes with high precision, versatility in cutting different materials, and ability to achieve high surface finishes make it a popular choice for a wide range of applications. Additionally, the durability and long-lasting performance of electrode wire make it a cost-effective solution for industries that require reliable and efficient cutting processes. Overall, electrode wire plays a crucial role in the success of EDM wire cut machines, providing the precision and quality needed for today’s demanding industrial applications.