Components of an EDM Wire Cut Machine Structure

In the world of manufacturing, precision and accuracy are of utmost importance. To achieve these qualities, many industries rely on EDM wire cut machines. These machines use electrical discharges to cut through various materials with incredible precision. To fully understand how these machines work, it is essential to have a clear understanding of their structure and the components that make them function.

At the heart of an edm wire cut machine is the power supply unit. This unit provides the necessary electrical energy to generate the electrical discharges used for cutting. It is responsible for converting the input power into the required voltage and current levels. The power supply unit also ensures that the electrical discharges are delivered in a controlled and consistent manner, allowing for precise cutting operations.

Connected to the power supply unit is the control unit. This unit acts as the brain of the machine, controlling and coordinating all the different components. It receives input from the operator and translates it into commands that the machine can understand. The control unit also monitors various parameters such as wire tension, cutting speed, and flushing pressure to ensure optimal performance.

One of the most critical components of an EDM wire cut machine is the wire guide system. This system consists of a series of pulleys and guides that guide the wire through the cutting process. The wire guide system ensures that the wire remains taut and properly aligned, allowing for accurate and precise cuts. It is essential for the wire to be properly guided to prevent any deviations or errors during the cutting process.

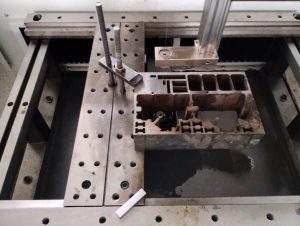

Another crucial component is the worktable. The worktable provides a stable platform for the material being cut. It is typically made of a non-conductive material to prevent any interference with the electrical discharges. The worktable can be adjusted in various directions to accommodate different cutting angles and positions. It is essential for the worktable to be level and properly aligned to ensure accurate and consistent cuts.

The wire tensioning system is responsible for maintaining the proper tension in the wire during the cutting process. This system ensures that the wire remains taut and does not sag or deviate from its intended path. Proper wire tension is crucial for achieving precise and accurate cuts. The wire tensioning system is typically adjustable, allowing for fine-tuning to meet specific cutting requirements.

Flushing is another critical aspect of the EDM wire cut machine structure. Flushing refers to the process of removing debris and particles from the cutting area. This is achieved by using a dielectric fluid, which is continuously circulated through the cutting zone. The dielectric fluid not only removes debris but also helps to cool the wire and prevent it from overheating. Proper flushing is essential for maintaining the integrity of the cutting process and ensuring high-quality cuts.

The components of an EDM wire cut machine structure is crucial for anyone involved in the manufacturing industry.