edm wire cut feed rate

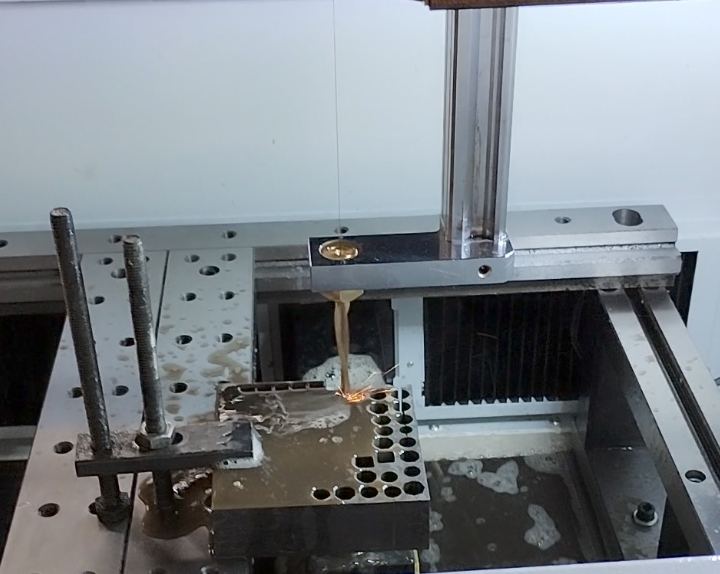

The feed rate of edm wire cut machine is the electrode wire feed rate relative to the workpiece after discharge machining,when the electric discharge machining the workpiece,control software can send the driving single to the worktable drive motor to move in accordance with the drawing tracks,exactly the wire feed rate must follow the workpiece eroded rate and maintain a suitable discharge distance for the next work step.So optimizing feed rate fo edm wire cut machine is impotant to the machining efficiency,surface finish and accuracy for the metal parts.

The primary benefit of optimizing the feed rate of an EDM wire cut machine is increased efficiency. By selecting the feed rate parameters, the machine will be able to cut more parts in a shorter amount of time. This will result in a higher output of parts and a shorter production time.

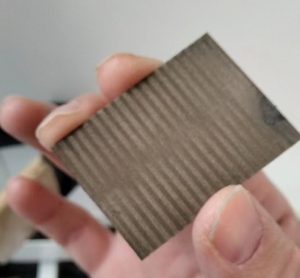

Another benefit of optimizing the feed rate of an EDM wire cut machine is improved surface finish. By adujusting the feed rate parameters, the electric diacharge will be able to work on the surface of workparts more evenly.that allow the surface finish be better.The inappropriate feed rate of edm wire cut will lead to rough surface of parts,that can reduce the production quality.

Additionally, optimizing the feed rate can also reduce the amount of wire used, resulting in cost savings.optimizing the feed rate of an EDM wire cut machine can also reduce wear and tear on the electrode wire. Too fast ot too slow feed rate which can increase loss for wire or machine the part more slowly. This will help to extend the service life of the electrode and reduce the use cost.

In conclusion, optimizing the feed rate of an EDM wire cut machine can provide numerous benefits, including increased efficiency, improved surface finish, and reduced wear and tear on the machine. By optimizing the feed rate, manufacturers can maximize the performance of their EDM wire cut machines and produce higher quality parts in a shorter amount of time

In order to optimize the machining quality, it is important to select a EDM wire cut machine feed rate that is appropriate for the material being machined. Generally, a higher feed rate is recommended for harder materials, while a lower feed rate is recommended for softer materials. Additionally, it is important to monitor the wire temperature and condition during the machining process in order to ensure that the wire is not becoming overheated or deformed.

By understanding the impact of different feed rates on the machining quality, it is possible to optimize the EDM wire cut process and produce parts with the highest possible quality.