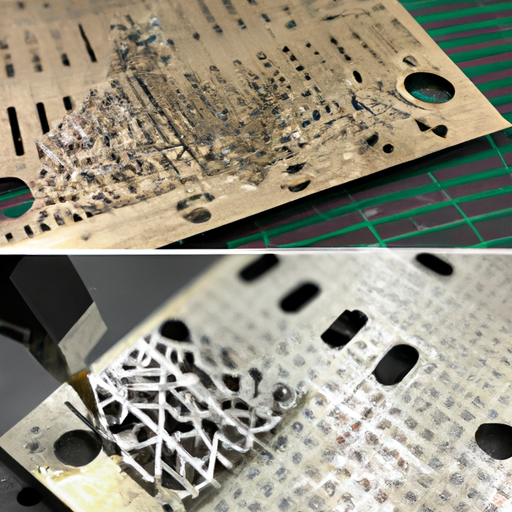

laser cut vs edm wire cut

Laser cutting and edm wire cut machine are two of the most popular manufacturing techniques used in the industry today. Both processes offer distinct advantages and disadvantages, and it is important to understand the differences between them in order to make an informed decision when selecting a manufacturing technique. This article will compare the pros and cons of laser cutting and EDM wire cut machine in order to help you make the best choice for your project.

The primary advantage of laser cutting is its speed and accuracy. Laser cutting is a fast and precise process that can be used to cut a variety of materials, including metals, plastics, and composites. The laser beam is able to cut intricate shapes with a high degree of accuracy, making it ideal for complex designs. Additionally, laser cutting is a non-contact process, meaning that it does not require any physical contact with the material being cut, which reduces the risk of damage to the material.

The primary disadvantage of laser cutting is its cost. Laser cutting is a relatively expensive process, and the cost of the equipment and materials can be prohibitive for some projects. Additionally, laser cutting is limited to two-dimensional shapes, so it is not suitable for three-dimensional designs.

edm wire cut machine is slower but more precise process than laser cutting.the efficiency of wire edm is 90 to 300mm²/min, The process uses a thin wire to cut through the material,and the wire is able to cut intricate shapes with a high degree of accuracy. Additionally, EDM wire cut machine is a non-contact process, meaning that it does not require any physical contact with the material being cut, the workpiece thickness wire edm cut is more than the laser cut machine,at present,the max.thickness for edm wire cut machine cutting metal is 1200mm,but the thickness of laser cut is less than 50mm.edm wire cut machining process video

The primary disadvantage of molybdenum wire edm is its cutting efficiency. the diameter of thin wire is 0.08 to 0.25mm,that carries a current less than 15A.Therefore,the efficiency is lower than laser cut, Previously,edm wire cut machine is limited to two-dimensional shapes, but the latest edm wire cut machine can machine three-dimensional products by installing 5th and 6th axis on the worktable.

Both laser cutting and edm wire cut offer distinct advantages and disadvantages. Laser cutting is a fast and precise process that is ideal for complex designs, but it is relatively expensive. EDM wire cut is a slower but more precise process, and it is lower cost and power. Ultimately, the best choice for your project will depend on your specific needs and budget.